About the Manufacturing Xperience Center

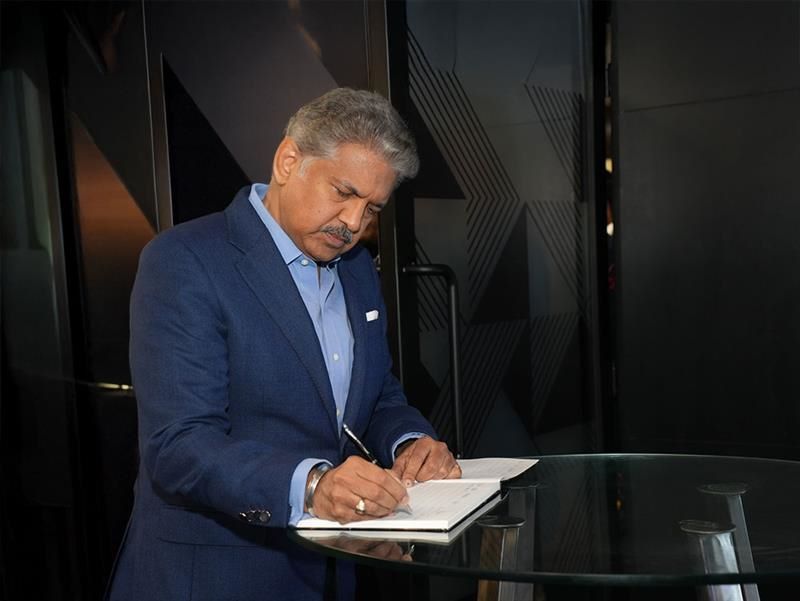

Tech Mahindra, a leading global provider of technology consulting and digital solutions to enterprises across industries, has announced the opening of an advanced Manufacturing Xperience Center was inaugurated by Anand Mahindra, Chairman of Mahindra Group, and Mohit Joshi, CEO and Managing Director of Tech Mahindra in Chennai on January 17, 2025.

MoreTech Mahindra, a leading global provider of technology consulting and digital solutions to enterprises across industries, has announced the opening of an advanced Manufacturing Xperience Center was inaugurated by Anand Mahindra, Chairman of Mahindra Group, and Mohit Joshi, CEO and Managing Director of Tech Mahindra in Chennai on January 17, 2025.

Tech Mahindra is redefining the future of manufacturing with the Manufacturing Xperience Center—a state-of-the-art facility designed to innovate, transform, and shape the industry’s future. More than just a space, this cutting-edge hub is a catalyst for groundbreaking solutions, where advanced technologies meet visionary thinking to drive manufacturing excellence on a global scale.

Less

For me, this is what we call a ‘RISE’ moment when we live up to our potential & create a facility & experience that is second to none in the world. BRAVO!

Executive Briefing Center

EBC is a state-of-the-art facility that fosters innovation, collaboration, and strategic guidance for manufacturing leaders. By providing interactive demonstrations and collaborative discussions, we empower manufacturers to navigate the complexities of today’s industrial landscape, enhancing operational resilience and adaptability to future demands.

Innovative Demonstrations

Hands-on access to cutting-edge technologies driving the future of manufacturing.

Curated Experiences

Tailored sessions with industry experts to address specific manufacturing challenges and opportunities.

Executive Visioning and Collaboration

Engage with thought leaders to develop actionable strategies for business transformation.

Our Industry-Specific Zones

The A&D zone highlights using drones to enhance efficiency, safety, and decision-making in manufacturing. Drones optimize processes, streamline inventory management, improve facility inspections, and support quality control and energy efficiency.

- Drones in Manufacturing: Drones provide aerial insights into material flow and workflow bottlenecks, streamline inventory management with automated stock counts using RFID or barcode scanning, enhance facility inspections with thermal imaging and AI-powered analytics, and boost security with real-time perimeter monitoring.

- Warehouse Modernization: Modernizing warehouses with Digital Twin, AI, and Automation improves operational efficiency. Digital Twin technology offers real-time visualization, AI drives intelligent decision-making, and automation streamlines operations, leading to cost savings and productivity gains.

The SFS zone addresses inefficiencies in manufacturing operations by leveraging advanced technologies to enhance efficiency, improve workplace safety for workers, and ensure seamless collaboration between machines and humans.

- The focus lies on six key areas: Digital Workforce, Reliable Equipment, Robust Quality, Efficient Production, Predictive Supply Chain, and Green Factory.

- Process Genealogy: Tracks and documents materials, processes, operators, and equipment using RFID, Barcode, and Pick Light systems for precise part identification and error-free assembly.

- AI Vision: Enhances safety, quality, and visual operator guidance within pick-to-light systems, boosting manufacturing efficiency.

- Maintenance Management: Uses sensors to monitor vibration, temperature, and pressure, enabling predictive maintenance and ensuring zero breakdowns.

- Process Adherence: Integrates smart tightening tools for fault-free processes and in-process quality checks.

- End-of-line quality Check: This process utilizes collaborative robots and vision systems for accurate end-of-line inspections, with digital check sheets for efficient, paperless quality management.

The Automotive zone features solutions like REDCAP for ELV recycling and "Feature on Demand" for luxury vehicles. REDCAP connects car owners, recyclers, garages, and informal players, while "Feature on Demand" allows instant activation of car features via a mobile app and OTA updates. It also includes a solution for remanufactured engines, addressing quality, delivery, and cost concerns.

- REDCAP: Connects the Indian ELV Recycling ecosystem, offering transparent vehicle recycling and fair pricing. Recyclers get real-time insights, garages access high-quality parts, and informal players can formalize and grow their businesses.

- Feature on Demand: This feature enables luxury vehicle owners to activate features like ventilated seats and heated steering wheels through a mobile app and OTA updates, providing additional revenue and customer engagement.

- Remanufactured Engines: A digital remanufacturing platform addresses fleet owners' quality, delivery, and cost concerns, including service center collaboration, planning, track and trace, quality management, and AI models for engine life prediction.

The CMM zone showcases innovative digital solutions that enhance both industries' efficiency, safety, and customer engagement. These zones highlight the transformative power of advanced technologies in real estate and mining operations.

- MetaLiving: Offers an immersive Metaverse experience for homebuyers, allowing virtual tours and interior customization. This enhances customer engagement and satisfaction, increasing property viewings and sales conversions.

- Connected Mine: Enhances mining operations with real-time monitoring, fleet management, planning and scheduling, and workforce management. This integrated approach maximizes output and sets new standards for efficiency and safety.

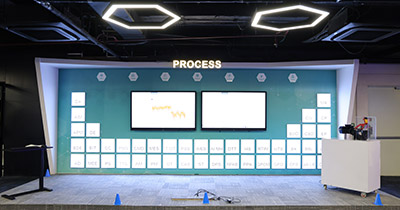

The Process zone uses distributed control systems (DCS) and unified operational command centers (UOC) to prevent unplanned shutdowns in chemical plants. It also features AI-powered predictive analysis for optimizing yield and quality and AR-based solutions for training and maintenance.

- Distributed Control System (DCS): This system monitors and controls processes in real-time, reducing the risk of unexpected shutdowns.

- Unified Operational Command Center (UOC): This center enhances coordination and decision-making for plants with multiple sites, integrating Asset Information and Performance Management (AIM & APM) to improve overall plant performance.

- AI-powered Predictive Analysis: Uses historical data and real-time inputs to predict and prevent issues, optimizing yield and quality.

- AR-based Solutions: Provides training, safety protocols, operational services, and remote SME support, reducing downtime and improving safety compliance. AR-based training and remote support can cut training costs by 30%.

The Industrial zone focuses on EquipmentWise. This model helps customers make data-driven decisions by combining IT, OT, and ET data with advanced AI/ML analytics. The solution aims to improve equipment performance, safety, and emission reduction.

- EquipmentWise: Companies that use heavy equipment are moving towards an asset-light model, where instead of buying equipment, they lease it on an outcome-based model. This requires IT technology solutions to manage business requirements effectively. The platform created by Tech Mahindra helps customers (equipment manufacturers, equipment users, and service providers) make data-driven decisions by combining data from IT, OT, and ET and performing advanced AI/ML analytics.

Gallery

Get In Touch

Need more information?

We will take approximately 3-5 working days to respond to

your enquiry.